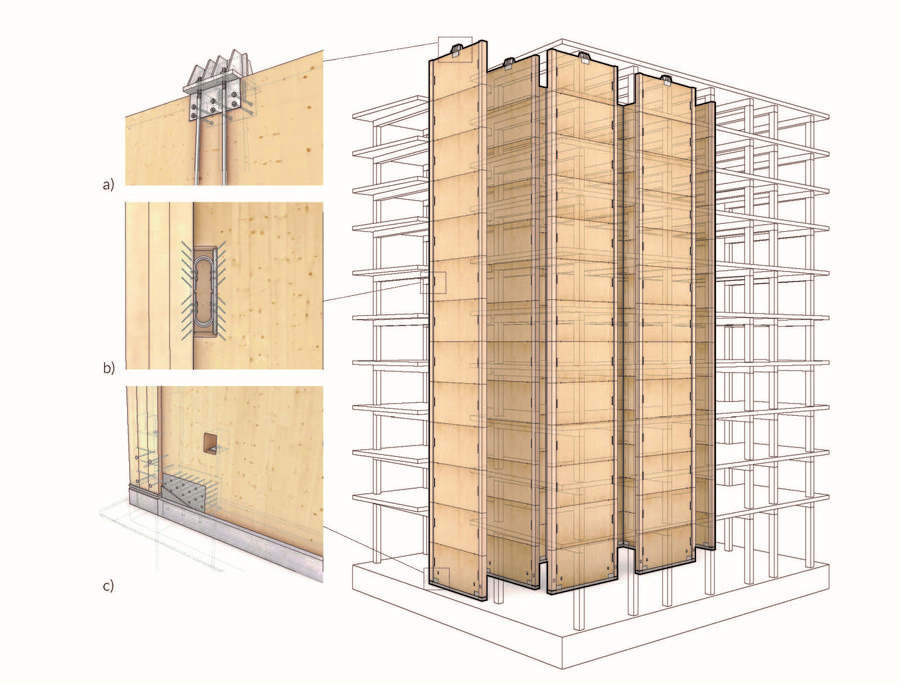

LEVER's design for Framework, the first wood high-rise approved for construction in the U.S., employs an innovative, first of its kind rocking wall core made from nine-ply Cross-Laminated Timber (CLT). The memory of the devastating 2010 and 2011 earthquakes in Christchurch, New Zealand was still very fresh and close to home for members of the Framework project team when we first won the competition to develop Framework. We set out to design it as a sustainable, resilient, damage-resistant building that could serve as demonstration of mass timber’s structural and aesthetic capabilities for for tall buildings in seismic zones.

The Framework Building. Our team won a USDA and Softwood Lumber Board competition to develop this groundbreaking project, requiring extensive research and testing. Data from Framework is open-source - read more here.

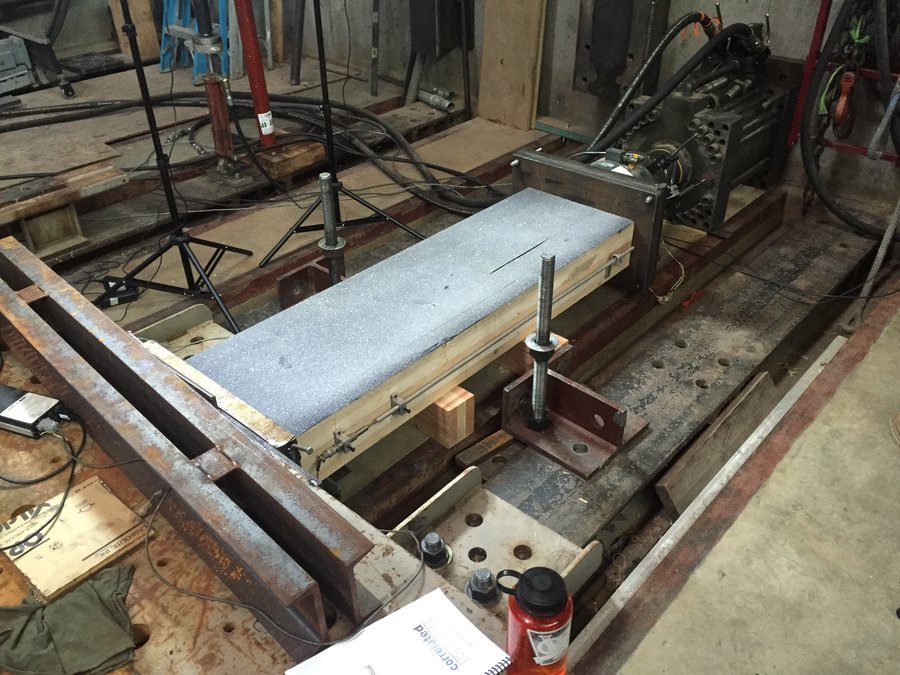

9-Ply CLT wall panel tests to verify flexural and shear stiffness tests performed at Oregon State University

From left to right: Framework's 9-ply CLT rocking wall lateral system; glue-laminated timber column and beam gravity system; and mass timber superstructure with 5-ply CLT floor decks.

Wall panel tests for flexural and shear stiffness

Floor panel crushing test

A successful ASTM-W119 2-hour wall, column, and UFP fire test

CLT walls, each comprised of thirteen 9-ply CLT panels measuring 10 ft x 20 ft, with deformation-controlled repairable / replaceable steel components.

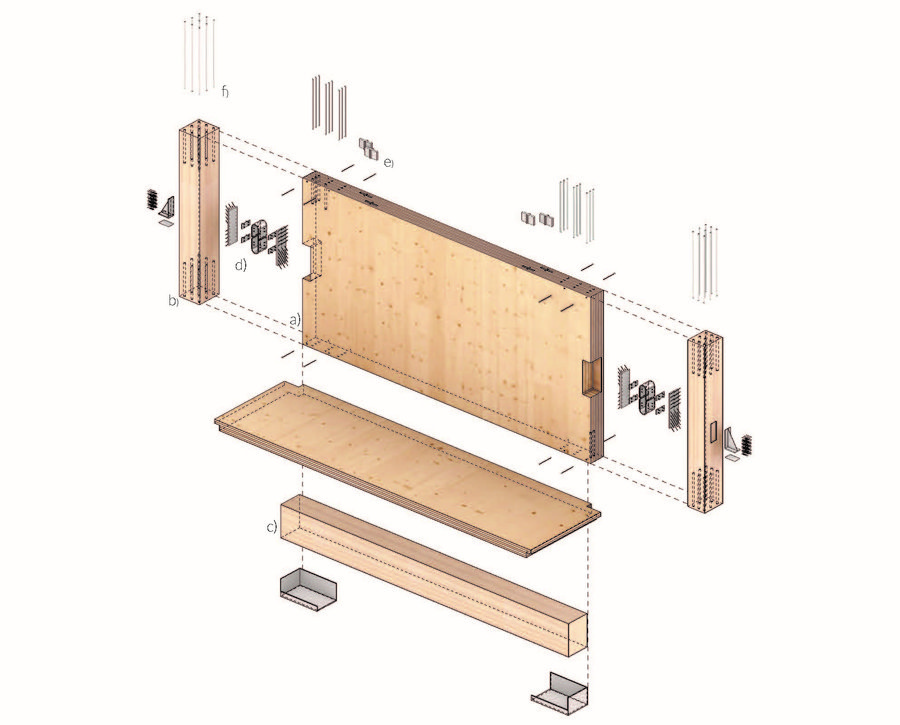

CLT wall and bounding beam assembly: (a) 10 ft. x 20 ft. 9-ply CLT rocking wall segment with associated (b) bounding columns, (c) collar beam, (d) UFP connectors, (e) splice key, and (f) epoxy rod reinforcement. Wall segments were engineered for offsite prefabrication and shipment to the jobsite for sequential assembly.

CLT wall panel structural testing at Oregon State University. Structural tests were taken well beyond actual building demands to observe failure mechanisms in the CLT panels.